The contents of our website are intended exclusively for adults over the age of 18.

Please confirm that you are of legal age.

I am at least 18 years old

Confirm

The contents of our website are intended exclusively for adults over the age of 18.

Please confirm that you are of legal age.

I am at least 18 years old

ConfirmIn 2008, Pöschl Tabak created a second string to their bow with the development of their own cigarette production in the field of smoking tobacco. Here, the company focuses, among other things, on additive-free factory cigarettes branded "PUEBLO".

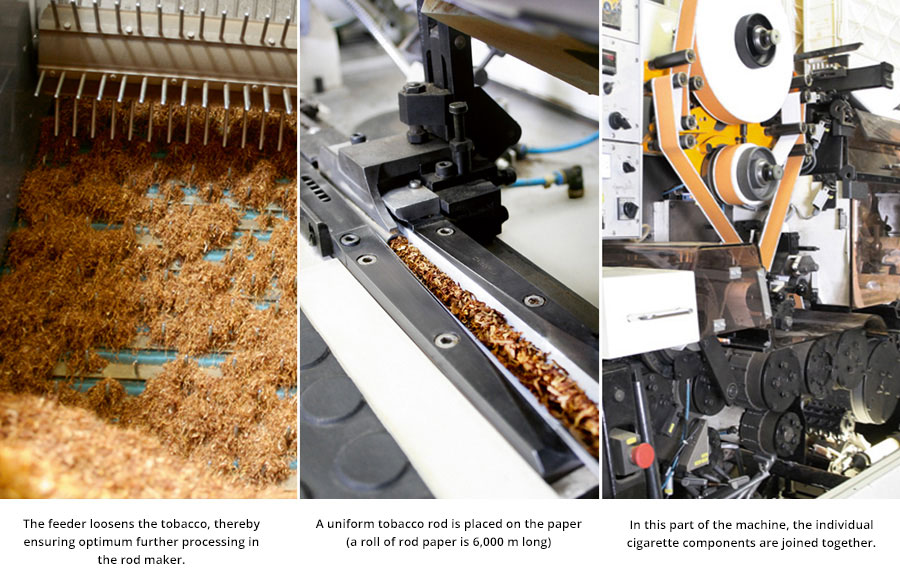

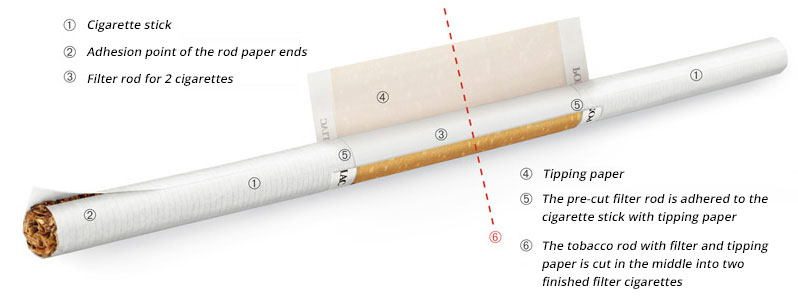

back to productsCut, loose tobacco is already loosened up in the feeder and sucked through a pipe for further processing into the storage container of the cigarette machine. Through the suction, the tobacco fibres are pre-formed into a uniform tobacco rod and placed on the rod paper. This is then glued together and the resulting “endless” tobacco rod cut into equal cigarette sticks. Two cigarette sticks each and one pre-cut filter rod are wrapped with tipping paper, glued together and cut through in the middle – and the filter cigarette is finished. Electronic measurement units between the working steps ensure exactly equal tobacco quantities, levels of moisture and drawing resistances.

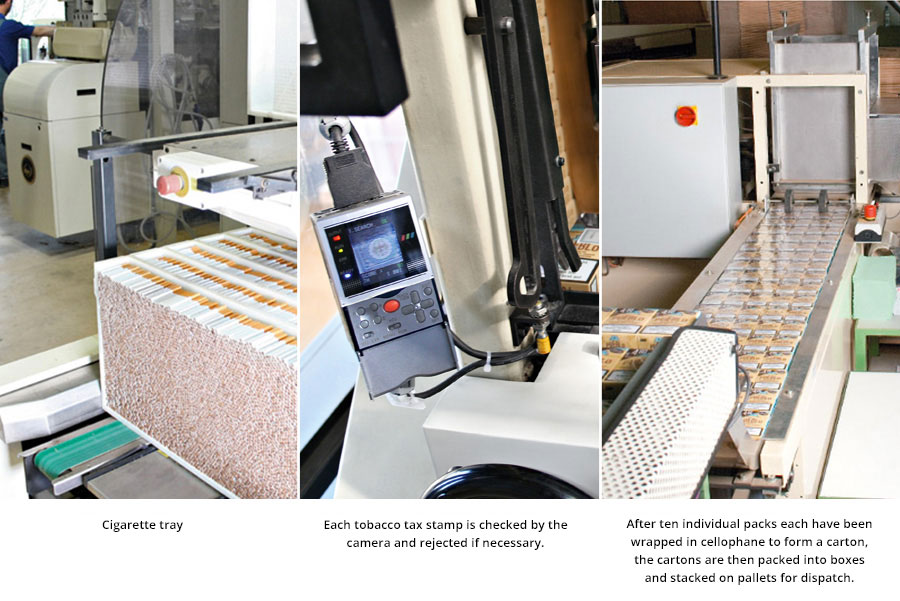

The filter cigarettes are either filled into containers or immediately forwarded to the packaging unit. In a given quantity, the cigarettes are wrapped into an inner foil. Protected in this way, the collar and the pre-cut are folded around and bonded by glue points. Again, measurement devices check the correct quantity and processing. After the application of the tax stamp, the packs are wrapped in cellophane and packaged in cartons of 10, labelled and packed in boxes.